INDUSTRIAL

VALVES

INSTRUMENTATION

VALVE AUTOMATION

|

|

Special Features: Clear Water Having Turbidity upto 5000 ppm and Temperature upto 45° C.

Other Fluids with Maximum Pressure / Temperature Conditions within the Scope of IS: 14846.

Valves can also be Supplied upto 180° C Working Temperatures with Special Design, Subject to

Working Pressure Imitations.

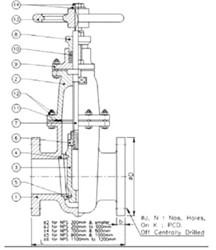

Sailant Constructional Features

Combination of Excellent Design Features of Reputed Overseas Valve Brands

Rigid and Sturdy Design with Minimum Loss of Head Across the Valve Perfect Interchangeability

of Components Assured Parallelism Between Side Flanges Assured Equal Taper Between Wedge

Faces Perfect Machining and Pressing of Body and Wedge Rings Excellent Finish on Spindle

Threads Resulting in low Friction and Smooth Operation of Valves Long Service Life and Leak-

Tightness Even After Thousands of Open / Close Cycles

Accessories (Optional)

Position Indicator

By-pass Arrangement (200 NB and above sizes)

Repacking (Back Seat) Arrangement

Spur / Bevel / Worm Gear Arrangement (200 NB and above sizes)

Thrust Bearing Arrangement (200 NB and above sizes)

Channel and Shoe Arrangement ( Renewable )(300 NB and above sizes)

Locking Arrangement

Extension Shafting and Head Stock

Electric Actuator

Drain Plug

Chain and Chain Wheel Arran |

|

|

| |

| Technical Spicification |

|

| Techinical Data |

|

MANUFACTRING STRANDARD:NORMAL SIZE 50 MM TO IS 780 RATING PN-10 1.6

SIZE 350MM & Above IS 2906 RATING PN 0.4 TO PN06.PN 1.0 PN 16 End

Connection flanged ends to IS 1538(PART -IV)

INSPECTION AND TESTING STANDARD:NORMAL SIZE 50 AAM TO 300MM-IS 780 RATING PN 1.0 T0 PN 1.6 |

| |

| P NO |

Qty |

Nomenclature |

|

| 1 |

1 |

BODY |

C.I IS Material210 Gr.FG200 |

| 2 |

1 |

BONNET |

C.I IS 210 Gr.FG200 |

| 3 |

1 |

WEDGE |

C.I IS 210 Gr.FG200 |

| 4 |

2 |

BODY RINGS |

ASTM 217 Gr.CA 15/G.M |

| 5 |

2 |

WEDGE RINGS |

ASTM 217 Gr.CA 15/G.M |

| 6 |

1 |

WEDGE NUTS |

H.T. BRASS/C.M |

| 7 |

1 |

STEM |

13Cr STEEL TO AISI 410 |

| 8 |

1 |

GLAND |

C.I IS 210 Gr.FG200 |

| 9 |

1 |

STFFING BOX |

C.I IS 210 Gr.FG200 |

| 10 |

Req |

STEM PACKINGS |

GRAPHITED ASBESTOS |

| 11 |

1 |

BONNET GASKET |

CAF |

| 12 |

Req |

BONNET BOLTS & NUTS |

CARBON STEEL IS 1363 |

| 13 |

1 |

HAND WHEEL |

C.I IS 210 Gr.FG200 |

| 14 |

1-1 |

SET SCRWE WASHER |

CARBON STEEL |

|

|

| |

| HYDROSTATIC TEST PRESSURE IS-780 |

| SIZE |

PIN RATING |

BODY |

SEAT |

| 50 TO 300 |

1.0 |

1.5MPo |

1.0MPo |

| 50 TO JQO |

1.6 |

2.4MPo |

1.6 |

|

|

| HYDROSTATIC TEST PRESSURE IS-2906 |

| SIZE |

PN RATING |

BODY |

SEAT |

| 700 TO 1200 |

0.4 |

0.6MPo |

0.4MPo |

| 350 TO 1200 |

0.6 |

0.9MPo |

0.6MPo |

| 350 TO 1200 |

1.0 |

1.5MPo |

1.0MPo |

| 350 TO 600 |

1.6 |

2.4MPo |

1.6MPo |

| All Demension are in M.M |

|

|

| |

| IS 780 PN1.0&PN1.6 |

| SIZE |

50 |

65 |

80 |

100 |

125 |

150 |

200 |

250 |

300 |

..... |

...... |

..... |

..... |

..... |

| L Force TO Force-FF(PN1.O,PN1.6) |

215 |

230 |

230 |

255 |

266 |

280 |

318 |

355 |

380 |

...... |

..... |

.... |

...... |

..... |

| øD |

165 |

185 |

200 |

220 |

250 |

285 |

340 |

395 |

445 |

..... |

.... |

.... |

..... |

.... |

| B |

16 |

16 |

21 |

22 |

22.5 |

23 |

24.5 |

26 |

27.5 |

.... |

.... |

.... |

..... |

..... |

| øJ |

4 |

4 |

4 |

8 |

8 |

8 |

8 |

12 |

12 |

.... |

..... |

..... |

.... |

.... |

| N |

19 |

19 |

19 |

19 |

19 |

23 |

23 |

23 |

23 |

... |

... |

... |

... |

... |

| K:PCD |

125 |

145 |

160 |

180 |

210 |

240 |

295 |

350 |

400 |

..... |

...... |

..... |

..... |

... |

|

| |

| IS 2906- PN0.4,PN 0.6 PN 1.0 &PN1.6 |

| SIZE |

300 |

400 |

450 |

500 |

600 |

700 |

750 |

800 |

900 |

1000 |

1100 |

1200 |

..... |

..... |

| L FACE TOFACE FF(PN0.4) |

..... |

..... |

..... |

..... |

..... |

635 |

685 |

700 |

740 |

760 |

780 |

810 |

...... |

..... |

| L FACE TOFACE FF(PN0.6) |

435 |

470 |

500 |

525 |

555 |

900 |

950 |

1000 |

1100 |

1200 |

1300 |

1400 |

..... |

.... |

| L FACE TOFACE FF(PN1.0) |

550 |

600 |

650 |

700 |

800 |

1130 |

1200 |

1250 |

1380 |

1500 |

1650 |

1800 |

..... |

..... |

| L FACE TOFACE FF(PN1.6) |

690 |

750 |

820 |

880 |

1000 |

..... |

..... |

..... |

...... |

.... |

..... |

..... |

.... |

.... |

| øD |

505 |

565 |

615 |

670 |

780 |

895 |

960 |

1015 |

1115 |

1230 |

1340 |

1455 |

... |

... |

| B |

29 |

30 |

31.5 |

33 |

36 |

38.5 |

40 |

41.5 |

44 |

47 |

50 |

53 |

..... |

... |

| N |

16 |

16 |

20 |

20 |

20 |

24 |

24 |

24 |

28 |

28 |

32 |

32 |

..... |

... |

| øJ |

23 |

28 |

28 |

28 |

31 |

31 |

34 |

34 |

34 |

37 |

37 |

40 |

..... |

... |

| K:PCD. |

460 |

515 |

565 |

620 |

725 |

840 |

900 |

950 |

1050 |

1160 |

1270 |

1380 |

..... |

... |

|

| |

|

|

|

|

|